Tucson, AZ – Responding to the growing demand for fuel tanks that meet increasingly stringent clean air standards, Walbro Engine Management is expanding its multilayer fuel tank production capabilities with new facilities and equipment around the world.

Walbro’s multilayer fuel tanks are used in lawn and garden, recreational and marine products. Manufacturers in these markets are transitioning and positioning fuel tank technology to meet the stringent evaporative emissions standards being imposed on their products.

“As tighter and tighter evaporative emission regulations are implemented and enforced, our multilayer fuel tank technology provides customers with a reliable solution that ensures compliance to the end of a product’s life cycle, using a variety of fuels,” says Tony Martin, President and Chief Executive Officer, Walbro Engine Management.

“Our expanding manufacturing capacity and footprint, coupled with additional technical support personnel, will help ensure that our fuel tank business is positioned to bring the latest technical solutions to our customer base around the world,” according to Martin.

Walbro installed its third blow-molding machine in Cass City, Michigan at the beginning of this year. A current expansion of the Cass City facility is underway to house additional blow molding machines, with the fourth machine scheduled for installation in the fourth quarter of 2011.

Additionally, Walbro has established a blow-molding plant in Chonburi, Thailand in support of its customers in the Asia-Pacific Region. This facility is scheduled to be in production by the fourth quarter of 2011 and is positioned for multiple machine installations. With a multi-customer lineup, further expansion within the region is forecasted, aided by Walbro’s policy of extensive customer support including application engineering, validation capabilities, certification assistance and production startup.

Walbro hit the one millionth tank milestone in 2010 since installing the first machine in 2007. The Company expects to produce one million tanks within 2011 with forecasted annual production rates of two million units in 2012, and over three million for 2013 as demand continues to grow.

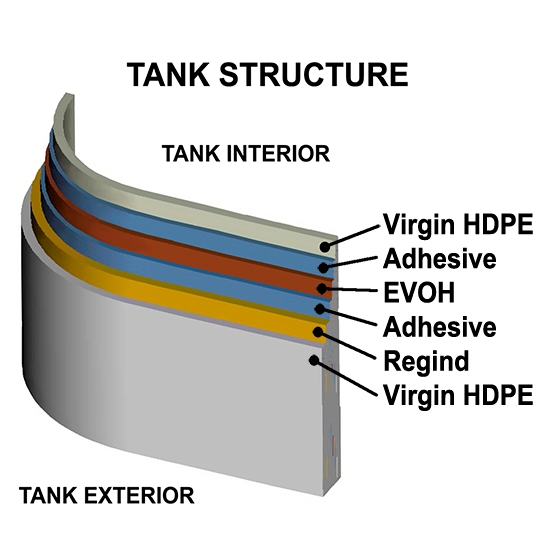

The success of Walbro’s non-metallic fuel tank line is based on the use of multilayer co-extrusion technology. The tank’s six-layer construction includes a vapor barrier that effectively contains hydrocarbon emissions, allowing it to meet evaporative emissions standards. In addition, Walbro’s multi-layer tanks are almost unaffected by ethanol, an important durability issue, especially as the use of ethanol fuels increases in the coming years.

While multi-layer fuel tanks are relatively new to the small engine arena and these markets, they are established technology in the automotive industry, where evaporative emissions standards first appeared. Dating back to 1992, Walbro’s pioneering efforts in multilayer tank technology for automotive applications puts the company on the leading edge of evaporative emissions solutions for today’s non-automotive applications ranging from small tanks for hand-held trimmers to larger tanks for riding mowers and recreational applications such as ATVs, two-wheelers and snowmobiles.

“Multilayer tanks are a well proven technology in terms of safety, emissions and durability;” states Christopher Quick, Global Fuel Systems Director, Walbro Engine Management. “Millions of multi-layer tanks are used in global automotive production annually, and are validated to meet expected vehicle life of up to 150,000 miles or 15 years.”

“Multilayer technology is extremely robust compared with other approaches, ensuring a reliable hydrocarbon barrier solution to meet product end-of-life requirements,” Quick adds. “Walbro’s multilayer tank technology provides consistent and repeatable low evaporative emission performance throughout the life of the product, which is a major advantage as evaporative emissions standards become more stringent in the future.”

“Customers in the small engine markets are fast becoming aware of the advantages of multilayer tanks versus other technologies and are driving the growth of multilayer tank technology, as was the case in the automotive market,” says Quick. “The use of multilayer tanks eliminates a lot of worry and uncertainty, especially considering long term durability compliance. The US Environmental Protection Agency (USEPA) and California Air resources Board (CARB) permit Walbro’s multilayer tank technology and our MLT products to be certified without the need for extensive, costly and time consuming tank testing.

“Walbro’s product offerings go beyond fuel tanks. Walbro is a full service supplier that can serve as a single source capable of integrated design, engineering, validation and production of fully assembled and tested tank systems ready for installation. Walbro can provide an integrated tank system, including a Walbro fuel pump and flange assembly, filtration, rollover valve and internal hoses, resulting in lower assembly and shipping costs.

Walbro Engine Management is a global market leader of engine management systems for the lawn and garden, recreational and marine, outdoor power equipment, and two-wheel small engine markets. Walbro Engine Management manufactures ignition systems, fuel injection, air/fuel management systems and fuel storage and distribution systems. Walbro Engine Management is a global organization with manufacturing and engineering facilities in China, Japan, Mexico, Thailand and the United States, with headquarters in Tucson, Arizona. Additional information regarding Walbro Engine Management is available at www.walbro.com/.

For more information, please contact:

Greg Marier

Walbro Engine Management

(989)872-7235